1 - Customer provides a concept via a sketch or a picture example based on instruments required in the panel. The requirements for this panel were to install and LX8000, a KRT2 8.33kHz radio, Outside Air Temperature gauge and OUDIE whilst creating space for an additional 57mm instrument for future upgrades and making the FLARM display more visible.

2 - LJPanels has an extensive database of instrument panels which include known obstructions and mounting limitations behind the panel.

3 - LJPanels develop a 3D CAD model from an extensive list of instruments and panel shapes based on the customer request. A database of known obstructions and mounting limitations behind the panel is checked to make sure that all components will fit. At this stage, the panel can be altered to suit the needs of the customer such as increasing leg room. In order to achieve the customers requirments it was necessary to purchase 57mm Air Speed Indicator and Altimeter.

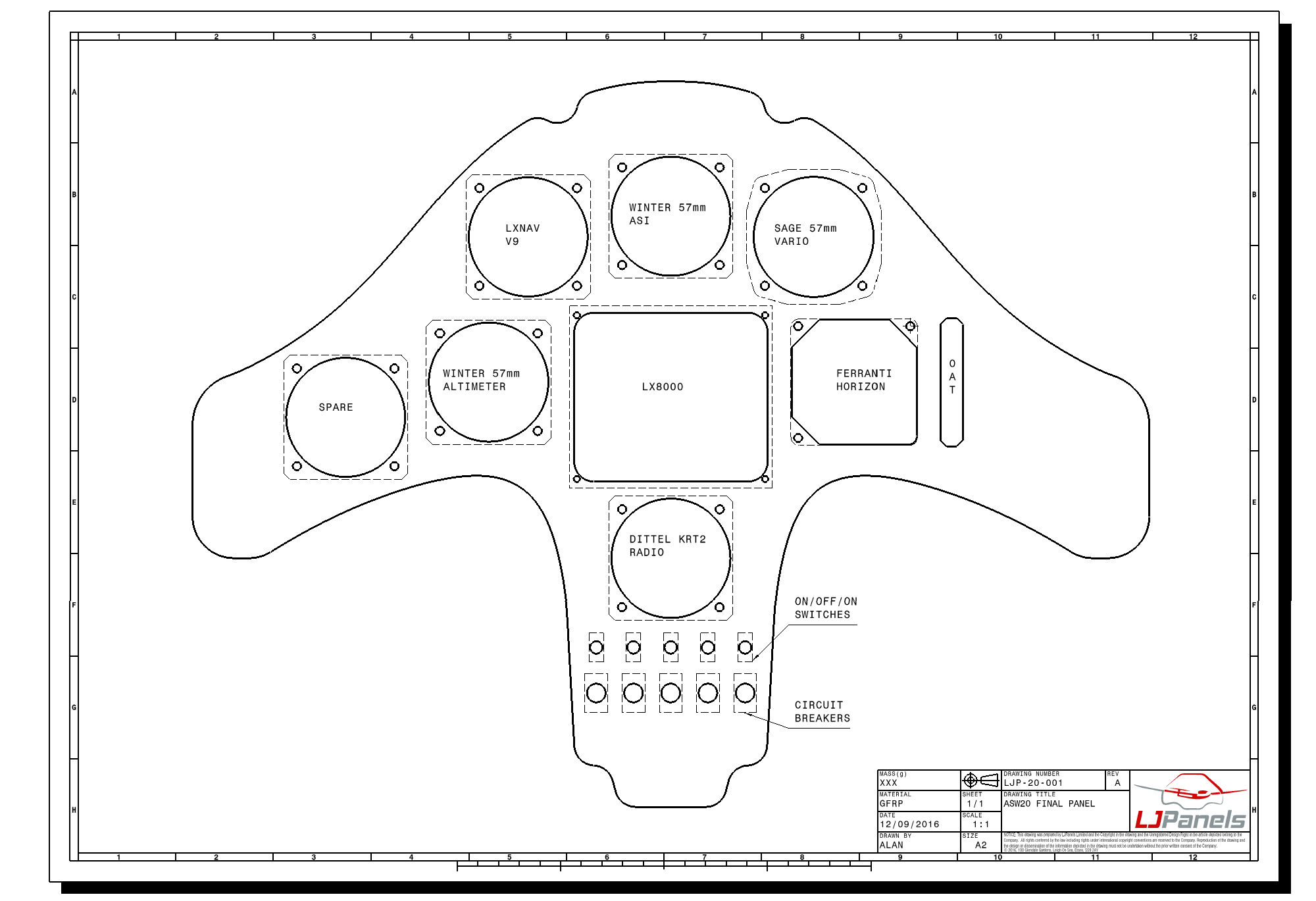

4 - The design is sent back to the customer in 2D format as a PDF (3D lightweight format is also available) for review. The use of 2D and 3D formats will allow the design to be visualised and the customer can be sure that all the requests are fully accommodated. The design review loop can be performed as many times as necessary until the customer is happy and provides design approval.

5 - Once the panel is approved LJPanels will begin the process of converting the concept into a cut panel. A new blank panel can be sourced or alternatively the old panel can be repaired and refurbished.

6 - The panel is painted to the customer specifications including an option for Nextel to allow the finished product to maintain the originality of the manufacturer supplied panel.

7 - All instruments are carefully installed in the panel and wiring harnesses created with quick release connectors (if required by the customer). Basic testing of the instrument installation is carried out at this stage. The panel is installed, cables and harnesses are neatly routed and secured in the aircraft and switches, fuses, circuit breakers etc are labelled.

8 - Installation is setup and tested before being handed over to the customer. LJPanels will provide wiring schedules and diagrams of the installation for easier modifications in the future.